Product Introduction

Molybdenum tray is a high temperature resistant container made of molybdenum or molybdenum-based alloy, mainly used for loading and transporting high melting point metals and alloys during high temperature sintering process. Molybdenum boat is widely used in special environments such as high temperature and high vacuum due to its excellent high temperature resistance, corrosion resistance, high strength and good electrical and thermal conductivity. Compared to molybdenum crucible, it has a simpler structure and lower cost.

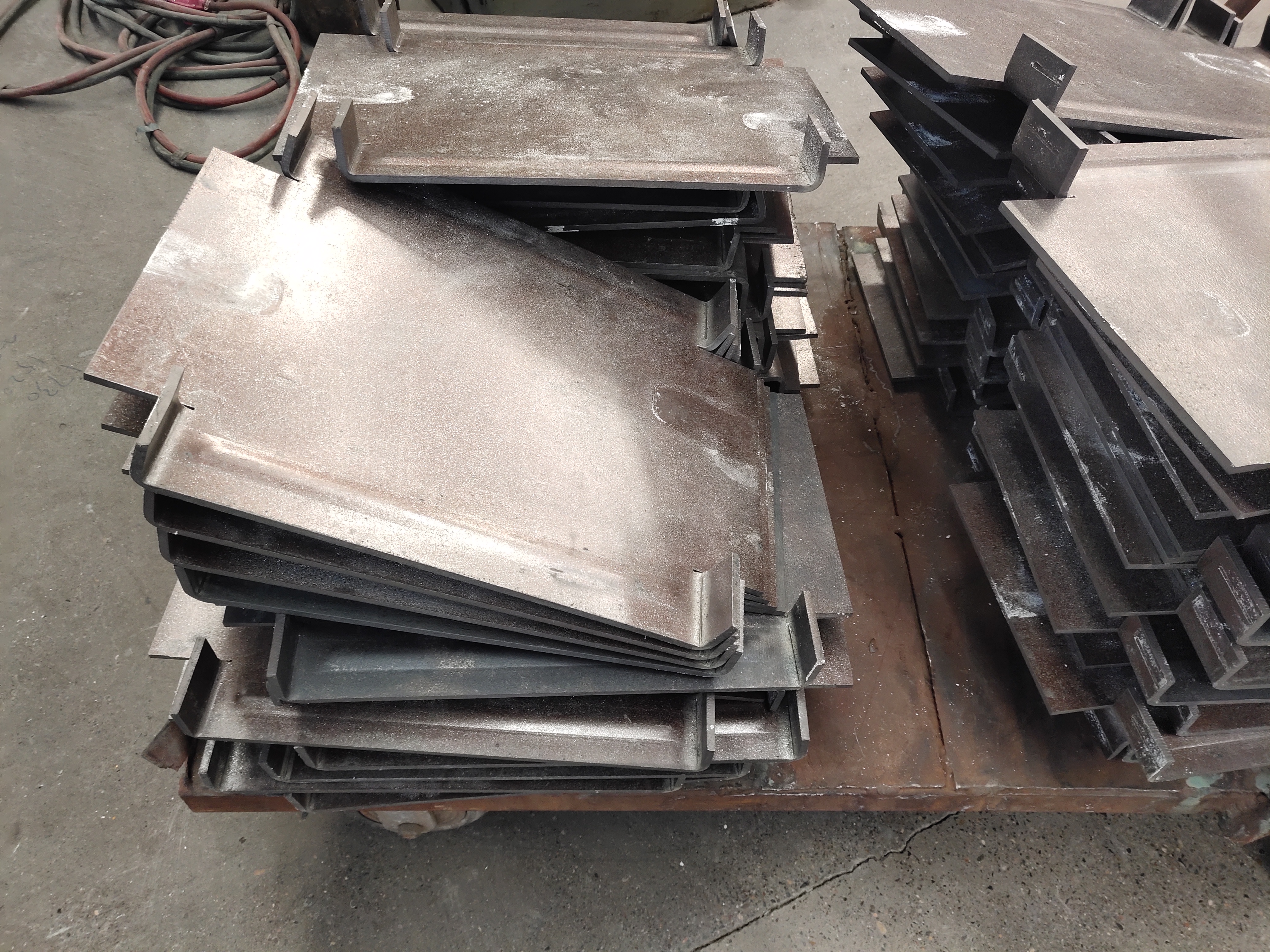

Our company produces and supplies various specifications of high temperature moly trays, sintering moly trays, and metallurgical moly trays, with a mature molybdenum material processing industry chain. We usually provide customized services, and can process moly trays according to the drawings or specific requirements provided by customers. In addition, we also provide sample processing services, which can replicate and produce products according to samples.

Product Material And Classification

Molybdenum trays are usually made of pure molybdenum or molybdenum alloys (such as molybdenum-lanthanum alloy, TZM alloy, etc.), which can withstand extremely high temperatures while maintaining structural stability and creep resistance.

1) Molybdenum-Lanthanum Alloy

To achieve particularly high ductility and creep resistance, we add small amounts of La2O3 to pure molybdenum. The stabilized microstructure and improved recrystallization behavior prevent premature embrittlement and fracture of our furnace components.

The advantages of Molybdenum-Lanthanum Alloys over pure molybdenum include:

Higher recrystallization temperature

Longer grain structure to improved ductility

Better creep resistance

2) TZM Alloy

We produce a particularly strong material by adding titanium and zirconium to pure molybdenum to strengthen its microstructure. The Mo-Ti solid solution and Ti-Zr carbides ensure excellent strength at temperatures up to 1400°C.

The advantages of TZM over pure molybdenum include:

Better creep resistance

Higher recrystallization temperature

Better high temperature stability

Product Features

The reason why molybdenum trays can be used in high-temperature environments is that molybdenum itself has the following key characteristics:

1) High temperature resistance:

Pure mo trays can withstand temperatures around 1100°C, while MoLa alloy boats and TZM alloy boats can withstand temperatures around 1900°C, and can maintain stability in high-temperature environments. Suitable for high-temperature heat treatment, sintering and other processes

2) High vacuum adaptability:

They are suitable for high vacuum environments and are often used in equipment such as vacuum furnaces.

3) Good corrosion resistance:

They can resist corrosion from most acids, alkalis and oxidants, and maintain performance in harsh environments

4) Excellent thermal stability and thermal conductivity:

They can still maintain their physical and chemical properties at high temperatures, and have good thermal conductivity, which helps to evenly distribute heat.

5) Low thermal expansion coefficient:

Mo trays expand very little when heated, which helps to maintain the stability of their shape and size, especially in repeated heating and cooling cycles.

6) High mechanical strength:

They have high mechanical strength at high temperatures and can withstand certain pressures and shocks.

7) Machinability:

They can be customized according to specific needs, such as welding, riveting, etc., to meet different usage requirements.

These characteristics enable molybdenum trays to maintain stable performance in high temperature environments, while having good creep resistance and ductility.

Product Advantages

1) The products are made of domestic high-quality raw materials, with excellent quality, good high temperature resistance and long service life.

2) We provide a better surface, and the smoothness of the surface also ensures that no substance will adhere during use

3) By using appropriate alloys and optimized production processes, we can improve the performance of molybdenum.

Packing

Molybdenum trays will be packed in standard export three-ply plywood cases

Plastic shock absorption foam is tightly filled in the box

Place desiccant in the box